Understanding Water Chiller Systems and Energy Efficiency

Water chiller systems are integral to modern HVAC infrastructure, providing critical cooling for commercial buildings, industrial processes, and data centers. These systems consume significant energy, often accounting for 40-50% of a facility’s total electricity use. With rising energy costs and environmental regulations, optimizing their efficiency has become a priority. Energy efficiency tests help identify performance gaps, reduce operational expenses, and align with sustainability goals. This article explores the methodologies, challenges, and innovations in achieving peak efficiency for water chillers.

Core Components and Operational Principles of Water Chillers

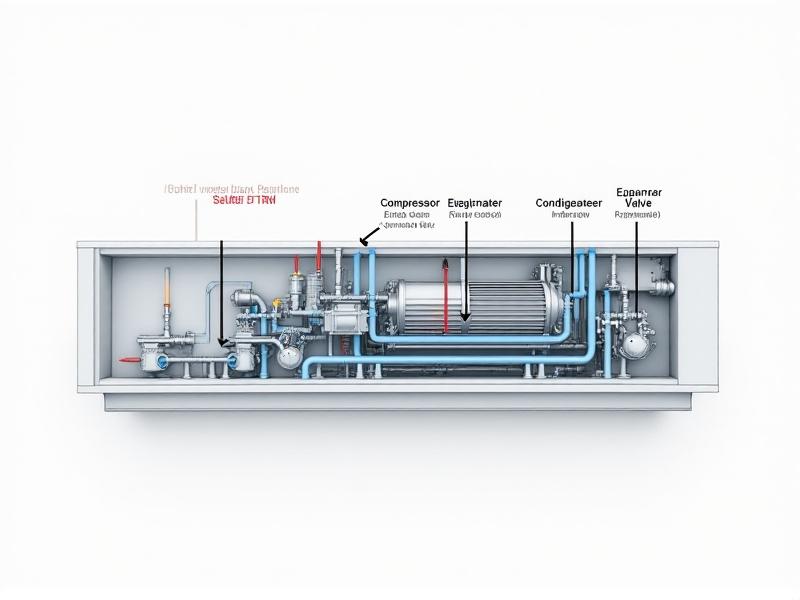

A typical water chiller consists of four primary components: the compressor, evaporator, condenser, and expansion valve. The compressor circulates refrigerant, which absorbs heat in the evaporator coil, cooling the surrounding water. The refrigerant then moves to the condenser, releasing heat to the external environment, before returning via the expansion valve to repeat the cycle. Centrifugal and screw chillers dominate the market, each offering unique efficiency profiles. Understanding these components and their interplay is essential for diagnosing inefficiencies and optimizing performance.

Why Energy Efficiency Matters in Chiller Operations

Energy-efficient chillers reduce operational costs and carbon footprints. For instance, improving a chiller’s Coefficient of Performance (COP) by 10% can save thousands annually in energy bills. Additionally, stricter regulations like the EU’s Ecodesign Directive mandate minimum efficiency standards. Beyond compliance, efficient systems enhance reliability, reduce wear and tear, and improve resale value. In industries such as pharmaceuticals or food processing, precise temperature control directly impacts product quality, making efficiency a operational necessity.

Key Performance Metrics for Chiller Efficiency

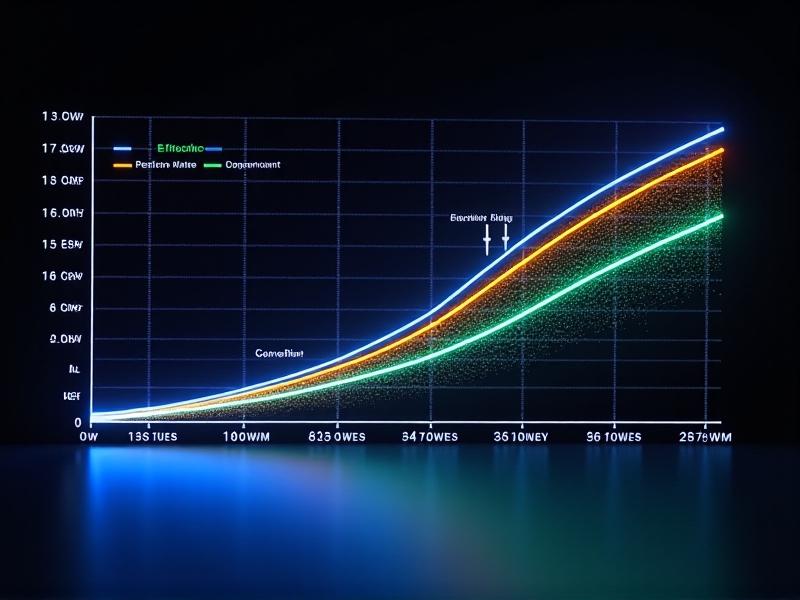

Metrics like COP (Coefficient of Performance), EER (Energy Efficiency Ratio), and IPLV (Integrated Part-Load Value) quantify chiller efficiency. COP measures cooling output divided by energy input, while EER reflects efficiency at peak load. IPLV evaluates performance across varying loads, crucial for real-world applications where demand fluctuates. Testing these metrics under standardized conditions (e.g., AHRI 550/590) ensures comparability. For example, a centrifugal chiller might achieve a COP of 6.0 under optimal conditions, while older models may lag below 4.0.

Standard Testing Protocols for Energy Efficiency

ASHRAE Standard 90.1 and AHRI 550/590 provide frameworks for testing chiller efficiency. These protocols define test conditions, such as condenser water temperature and ambient air quality, to ensure consistency. For certification, chillers undergo rigorous lab tests at full and part-load capacities. Field testing, though less controlled, offers insights into real-world performance. Tools like data loggers and thermal imaging cameras help technicians identify refrigerant leaks or insulation gaps during audits.Environmental and Operational Factors Affecting Efficiency

Ambient temperature, cooling load variability, and water quality significantly impact efficiency. High condenser water temperatures due to hot climates can reduce COP by up to 20%. Scaling from hard water insulates heat exchanger surfaces, impairing heat transfer. Partial load operations—common in commercial buildings—also strain systems not designed for variable demand. Predictive maintenance, variable speed drives, and free cooling modes mitigate these issues, ensuring optimal performance year-round.Case Study: Energy Efficiency Retrofits in Commercial Buildings

A 2022 retrofit at a Chicago office tower replaced two aging centrifugal chillers with magnetic-bearing models, achieving a 35% reduction in energy use. By integrating IoT sensors for real-time load adjustments, the system adapted to occupancy patterns, further optimizing consumption. The $1.2M project paid for itself in four years through utility savings and tax incentives. Such cases underscore the financial and environmental benefits of modernization.Best Practices for Maintaining High Efficiency in Chillers

Routine maintenance—cleaning coils, checking refrigerant levels, and calibrating sensors—prevents efficiency degradation. Installing variable frequency drives (VFDs) on pumps and compressors adjusts motor speeds to match demand, reducing energy waste. Thermal energy storage systems shift cooling to off-peak hours, leveraging lower electricity rates. Staff training ensures operators understand efficiency metrics and can respond to anomalies promptly.Technological Innovations Enhancing Chiller Efficiency

Magnetic-bearing compressors eliminate friction, reducing energy loss and maintenance. AI-driven platforms like BrainBox AI® analyze historical data to predict load changes and optimize setpoints. Meanwhile, absorption chillers powered by waste heat or solar energy offer fossil-free alternatives. Such innovations redefine efficiency boundaries, enabling COP values above 8.0 in cutting-edge systems.The Road Ahead: Sustainability and Smart Chiller Systems

The future of chiller systems lies in integration with smart grids and renewable energy. Hybrid systems combining solar thermal input with electric compression are gaining traction. Additionally, IoT-enabled chillers will autonomously adjust operations based on weather forecasts or energy pricing. As global standards evolve, the industry is poised to balance cooling demands with net-zero commitments, ensuring chillers remain both effective and environmentally responsible.Advertisement

Recommended Reading: Portable Cold Plunge Solutions for Travel

Comments

Leave a Comment

Your email address will not be published. Required fields are marked *