Understanding the Importance of Insulation in Outdoor Plunge Enclosures

Outdoor cold plunges and plunge pools have surged in popularity for their health benefits, from reducing inflammation to boosting recovery. However, maintaining these structures in varying climates demands robust insulation. Insulated enclosures serve as protective shells, ensuring temperature stability while shielding users from harsh weather. Without proper insulation, energy costs soar, and user comfort plummets. This section explores why insulation isn’t just a luxury but a necessity for outdoor plunge systems.

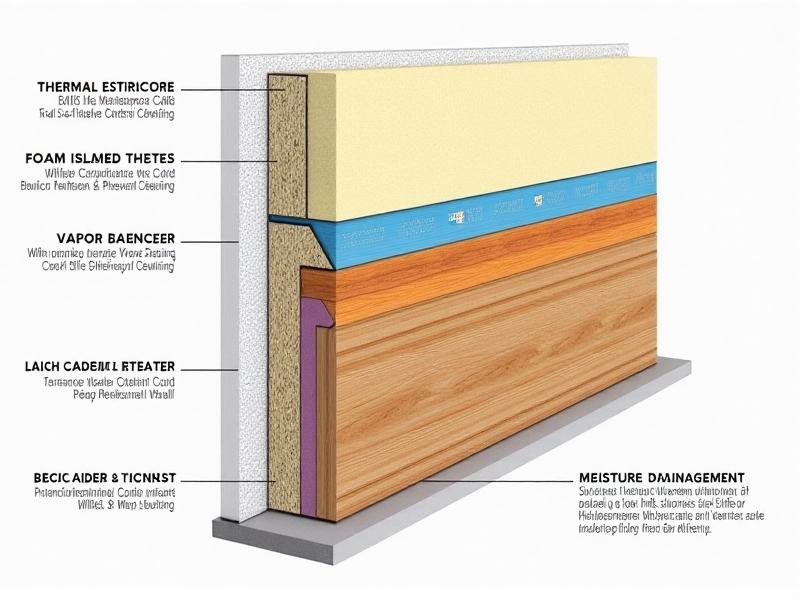

Material Selection for Optimal Thermal Performance

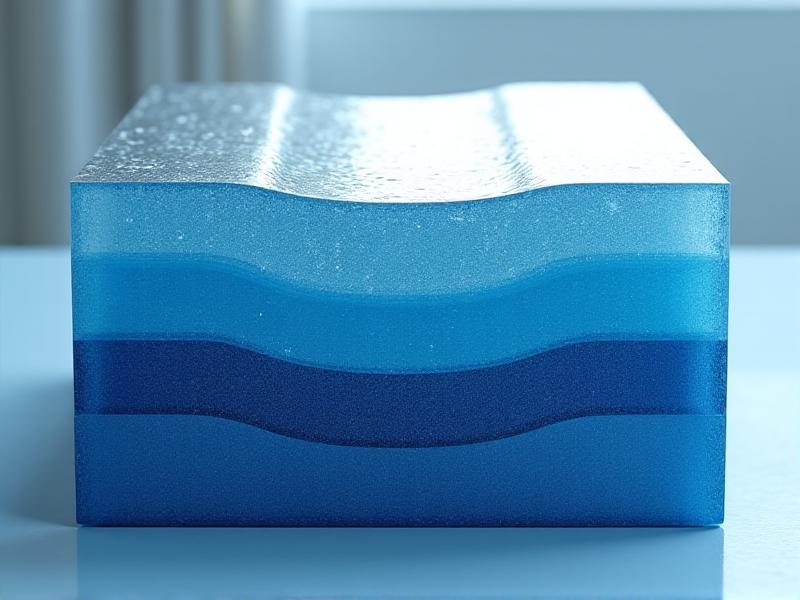

Choosing the right materials is critical for balancing insulation, durability, and aesthetics. Structural insulated panels (SIPs) with polyurethane foam cores offer high R-values, while thermally broken aluminum frames minimize heat transfer. For transparency without sacrificing efficiency, double-glazed glass with low-E coatings reduces radiant heat loss. This section breaks down material trade-offs and highlights innovations like vacuum-insulated panels (VIPs) that maximize space efficiency in compact designs.

Design Strategies for Heat Retention and Energy Efficiency

Effective enclosure design goes beyond material choice. Passive solar principles, such as south-facing glazing, can harness natural warmth, while automated thermal curtains provide after-dark insulation. Ground-source heat pumps integrated with enclosure HVAC systems further optimize energy use. Case studies reveal how combining these strategies can reduce heating demands by up to 40%, making year-round plunging feasible even in subarctic climates.

Weatherproofing and Moisture Management in Harsh Environments

Insulation fails when water intrudes. High-performance enclosures employ rainscreen cladding systems to create drainage planes, while silica gel breather membranes allow vapor diffusion without liquid penetration. This section examines critical details: sloped roofing to prevent ice dams, heated door thresholds to avoid snow ingress, and antimicrobial insulation coatings that resist mold in humid microclimates.

Ventilation and Air Quality in Sealed Plunge Environments

Airtight insulation risks stale air and humidity buildup. Energy recovery ventilators (ERVs) provide fresh air without losing heat, while CO2 sensors paired with automated louvers maintain safe oxygen levels. Learn how one Scandinavian spa uses geothermal pre-warming for incoming air, achieving 80% heat recovery efficiency while preventing the "stuffiness" common in traditional sauna designs.Blending Aesthetics with Functionality: Architectural Trends

Today’s plunge enclosures marry form and function. Cantilevered glass boxes create floating illusions over forest ravines, while charred timber (shou sugi ban) cladding offers natural fire resistance and striking textures. This section profiles designers pushing boundaries with biophilic elements—living green walls that improve insulation, or integrated stone benches that act as thermal mass buffers.Cost Considerations and Long-Term ROI

While premium insulation systems add 15-25% to upfront costs, their long-term payoff is compelling. Infrared thermography comparisons show how a well-insulated enclosure in Colorado maintains 102°F water temperature during -10°F nights using 60% less energy than a basic model. Tax incentives for energy-efficient structures and reduced maintenance needs further tip the scales toward smart insulation investments.Future Innovations: Smart Tech and Adaptive Insulation

The frontier of enclosure design lies in responsive systems. Phase-change materials (PCMs) embedded in walls absorb excess heat during the day, releasing it at night. Electrochromic glass transitions from clear to tinted based on UV intensity, while AI-driven systems learn usage patterns to anticipate heating needs. Prototype enclosures now adjust insulation properties dynamically—imagine walls that "thicken" during blizzards using telescoping insulation layers.Advertisement

Recommended Reading: Myokine Secretion & Muscle Recovery Links

Comments

Leave a Comment

Your email address will not be published. Required fields are marked *