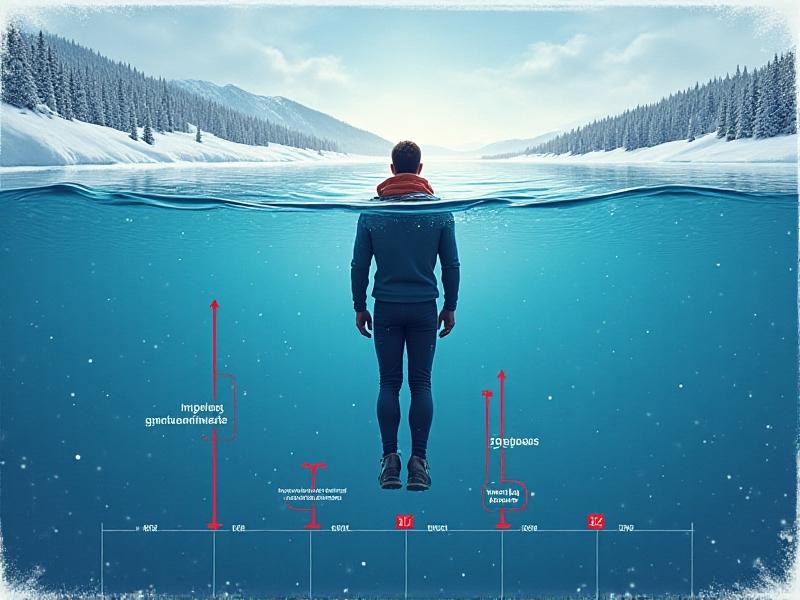

Understanding the Basics of Cold Plunge Tanks

Cold plunge tanks are specialized equipment designed for hydrotherapy, athletic recovery, and wellness. Their maintenance is critical to ensure hygiene, longevity, and performance. These tanks typically consist of a stainless steel or fiberglass structure, a chilling system, water filtration, and often UV or ozone sanitization components. Knowing the core parts helps identify maintenance priorities, from preventing bacterial growth to ensuring mechanical efficiency. Neglecting upkeep can lead to costly repairs, compromised water quality, or health risks.

Daily Cleaning and Hygiene Routines

Daily maintenance is the first line of defense against contaminants. Start by skimming the water surface to remove debris like hair or skin particles. Use a non-abrasive brush to scrub the tank’s interior, focusing on waterline residues. Test pH and chlorine levels with a digital meter or test strips—ideal ranges are 7.2–7.6 for pH and 1–3 ppm for chlorine. Add balancing chemicals if needed. Drain and refill water every 3–7 days, depending on usage frequency. Wipe down exterior surfaces with a mild detergent to prevent dirt buildup.

Weekly Maintenance Checks for Optimal Performance

Inspect mechanical components weekly. Check the chiller unit for unusual noises or leaks, and ensure its vents are dust-free. Examine filters for clogs—rinse or replace them as necessary. Test water pumps to confirm proper flow rates. Lubricate hinges or moving parts on access panels to prevent rust. Verify that temperature controls maintain a consistent range (typically 50–59°F). Document all observations in a maintenance log to track trends or recurring issues.

Monthly Deep Cleaning Procedures

Perform a thorough cleaning monthly. Drain the tank completely and scrub all surfaces with a hydrogen peroxide or vinegar solution to dissolve mineral deposits. Soak removable parts like jets and filters in a descaling agent. Inspect seals and gaskets for wear, replacing any cracked or brittle components. Sanitize plumbing lines by circulating a citric acid mix through the system. This prevents biofilm formation and ensures optimal water flow.

Proper Sanitization Techniques

Sanitization goes beyond basic cleaning. Use EPA-approved disinfectants like bromine or chlorine tablets, ensuring they’re compatible with your tank’s materials. For chemical-free options, consider UV-C light systems or ozone generators, which neutralize pathogens without altering water chemistry. Always rinse the tank thoroughly after chemical treatments to prevent skin irritation. Test sanitizer levels before each use to safeguard user safety.Preventing Algae and Bacterial Growth

Stagnant water and warm environments encourage microbial growth. Maintain water circulation even when the tank isn’t in use. Shock the water weekly with a high dose of chlorine or non-chlorine oxidizer to eliminate organic contaminants. Install an algaecide dispenser if the tank is exposed to natural light. Regularly clean shaded areas and corners where biofilm might develop unnoticed.Maintaining Water Temperature Consistency

Inconsistent temperatures strain the chiller and compromise user experience. Calibrate the thermostat monthly using a certified thermometer. Insulate exposed pipes to reduce energy loss. Ensure the chiller’s refrigerant levels are adequate and its coils are free of frost or debris. If the tank is outdoors, use a insulated cover during extreme weather to stabilize internal temps.Seasonal Maintenance Considerations

Adjust routines for seasonal changes. In winter, protect outdoor tanks from freezing with antifreeze additives or heated blankets. Summer demands more frequent filter changes due to higher usage. Inspect seals and structural integrity in spring to address wear from temperature fluctuations. Before seasonal shutdowns, perform a full system flush and apply protective coatings to metal parts.Addressing Common Issues and Troubleshooting

Cloudy water often signals imbalanced pH or poor filtration—test and adjust accordingly. Unusual noises from the pump may indicate air leaks or worn bearings. Persistent odors suggest inadequate sanitization or biofilm in plumbing. Keep a troubleshooting checklist handy and consult the manufacturer’s guidelines before attempting complex repairs.Safety and Compliance Best Practices

Ensure compliance with local health codes by documenting maintenance activities and water test results. Install anti-slip mats around the tank to prevent accidents. Use GFCI outlets for electrical components to avoid shocks. Train users on proper hygiene, like showering before entry, to minimize contamination risks. Regularly review safety protocols with staff or household members.Advertisement

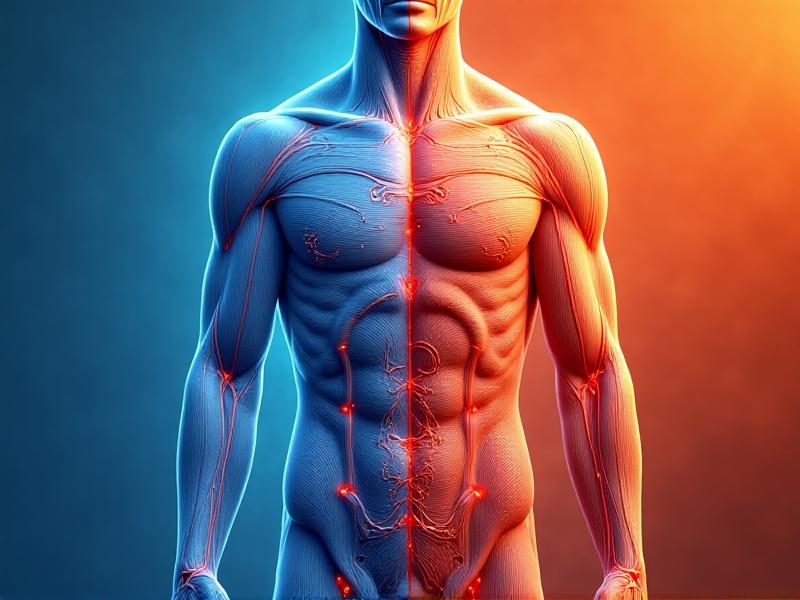

Recommended Reading: Vasoconstriction Dynamics in Cold Exposure

Comments

Leave a Comment

Your email address will not be published. Required fields are marked *