Understanding Cold Plunge Lid Insulation Basics

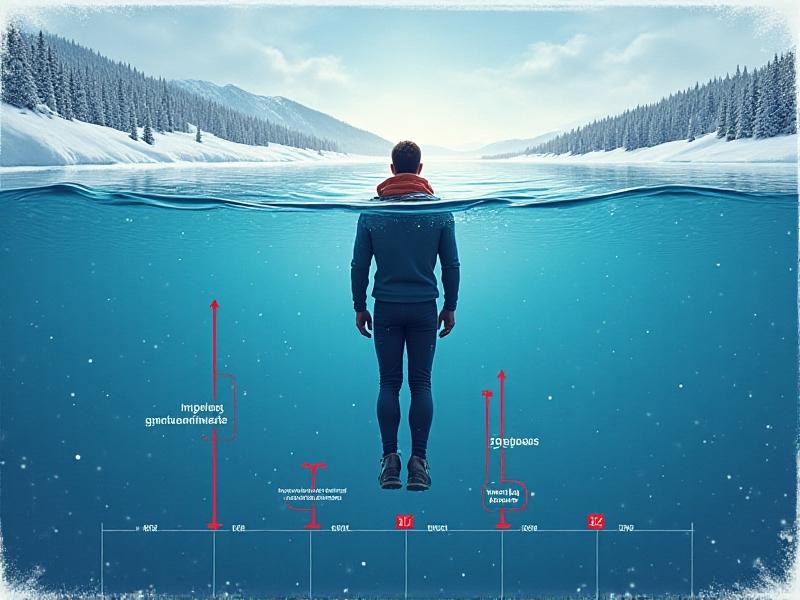

Cold plunge therapy has surged in popularity for its health benefits, but maintaining water temperature is critical. A lid’s insulation value determines how effectively it retains cold, reducing energy costs and enhancing user experience. Insulation works by slowing heat transfer—measuring this resistance (R-value) or conductance (U-value) dictates a lid’s performance. For cold plunge setups, higher R-values or lower U-values mean better thermal retention. Beyond numbers, factors like material composition, lid thickness, and environmental exposure influence real-world efficacy. A well-insulated lid not only preserves water temperature but also minimizes refrigeration cycles, extending equipment lifespan.

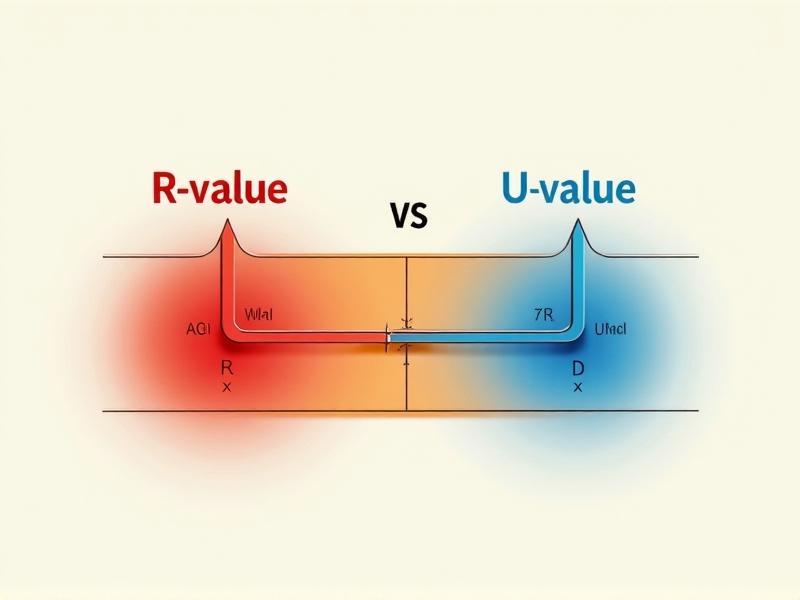

The Science Behind Insulation Value Ratings

Insulation ratings like R-value (thermal resistance) and U-value (thermal conductance) are foundational. R-value measures a material’s ability to resist heat flow—higher values mean better insulation. U-value, inversely, quantifies heat loss. For cold plunge lids, prioritizing materials with high R-values (e.g., ≥5 per inch) ensures minimal heat ingress. Environmental factors like humidity and temperature differentials affect these values. Closed-cell foams, for instance, maintain R-values better in damp conditions than fiberglass. Understanding these metrics helps users select lids that balance efficiency with practicality, avoiding over-engineering for moderate climates or under-insulating in extreme environments.

Materials and Their R-Value Comparisons

Expanded polystyrene (EPS: R-3.6–4.2 per inch) is affordable but susceptible to moisture. Extruded polystyrene (XPS: R-5) offers better moisture resistance. Polyisocyanurate (polyiso: R-6–6.5) excels in dry environments but degrades in cold. Aerogel (R-10+) boasts superior performance but at a premium cost. Vacuum-insulated panels (VIPs: R-25+) are cutting-edge but fragile. For most users, XPS or polyiso strikes a balance between cost and performance. Layering materials—like combining XPS with a reflective barrier—can enhance effectiveness without prohibitive expenses.

Practical Factors Affecting Insulation Performance

Beyond material choice, lid design impacts insulation. Gaps or poor sealing invite thermal bridging—where heat bypasses insulation. Weatherstripping and airtight seals mitigate this. Thicker lids improve R-value but add weight and cost. Ambient humidity can reduce foam effectiveness over time. Reflective coatings or radiant barriers complement traditional insulation by repelling external heat. Regular maintenance—checking for cracks, moisture intrusion, or compression—ensures sustained performance.

DIY vs. Commercial Lid Solutions: Pros and Cons

DIY lids using XPS foam and vinyl covers cost ~$100 but require precision in cutting and sealing. Commercial lids ($300–$800) offer warranties, optimized designs, and integrated handles. However, mass-produced lids may use lower-R materials to cut costs. DIY allows customization for odd-shaped tubs but risks imperfect insulation. Commercial options save time but limit flexibility. Evaluate based on budget, skill level, and specific needs.Sustainability in Cold Plunge Insulation Choices

Eco-conscious users can opt for recycled EPS or plant-based polyurethane foams. Avoid materials with HCFCs or formaldehyde. Aerogel’s durability reduces waste over time. End-of-life disposal matters—some foams are recyclable, while others release toxins if incinerated. Energy savings from high-efficiency lids also contribute to lower carbon footprints.Maintenance Tips for Long-Term Insulation Efficiency

Inspect lids monthly for cracks or water absorption. Replace swollen or moldy foam immediately. Reapply sealants annually. Store lids in shaded areas to prevent UV degradation. Use mild cleaners to avoid chemical damage. Proper care extends lifespan and maintains R-value integrity.Case Studies: Real-World Insulation Success Stories

A Minnesota wellness center cut energy costs 40% by upgrading to R-10 aerogel lids. A DIY enthusiast achieved near-commercial efficiency using layered XPS and foil barriers for under $200. A coastal gym avoided foam rot by choosing closed-cell polyiso despite lower R-values, proving context matters.Advertisement

Recommended Reading: UV Sterilization for Natural Water Exposure

Comments

Leave a Comment

Your email address will not be published. Required fields are marked *